Informazioni di Base.

Model No.

BP20

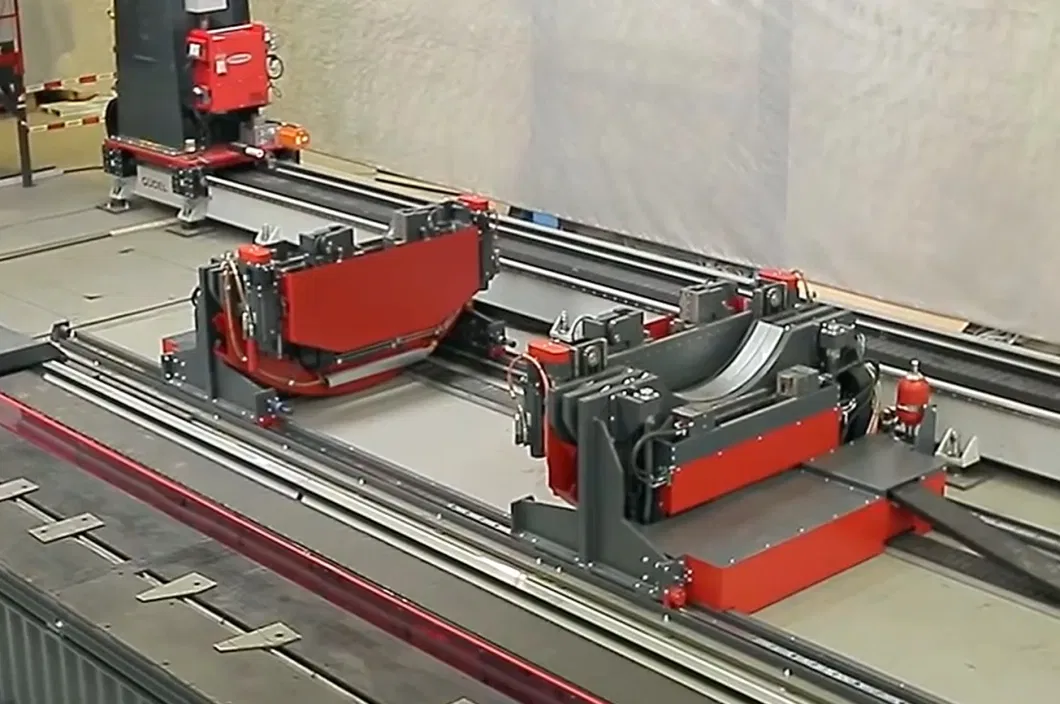

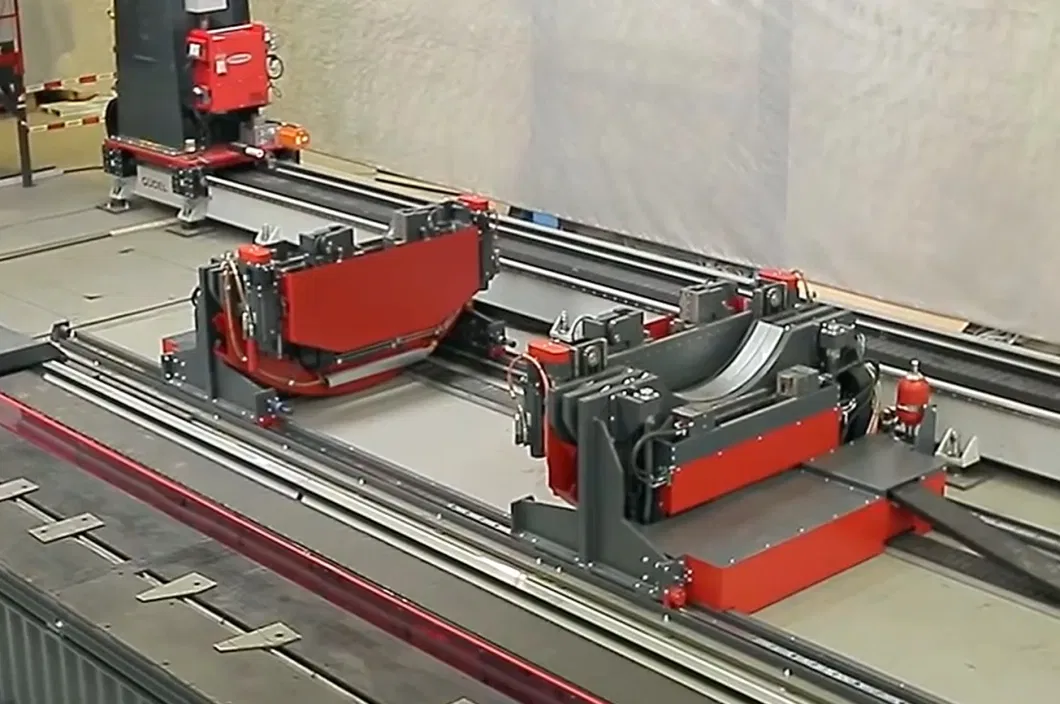

Saldatura Passando Rolls Tipo

Fixed and Lift

Saldatura Tipo Tilter

Combinazione flessibile

Condizione

Nuovo

tonnellate

15 tonnellate

bogie

incluso

fit

idraulico

Pacchetto di Trasporto

Nude

Specifiche

1200-2000

Marchio

DESAN

Origine

China

Codice SA

84688000

Capacità di Produzione

1000

Descrizione del Prodotto

Welding positioner is mainly used to placed the work piece in the best position for welding and assembling with the work bench elevating, turning, tilting , its series includes tilting, head and tail stocks ,elevating ,and double turning positioner, cradle type. The positioner can be supplied for interfacing with robot or welding manipulators ,to realize the welding automation. At the same time we can design and customize various type of special positioner according to the technological requirement and different work piece given by the customer.

Head & tail stock positioner widely used in all line of mechanical welding plant, deflection of workpiece can make parallel axis of rotation to ship welding seam deflection. The structural features:

+ worm gear and worm reducer, compact structure, high reliability.

+ slewing bearing providing higher resistance to overthrow force and torque.

+ former board cabinet, thickening, strength, higher stability.

+ welding box frame, high stiffness distortion.

+ Excellent welding wire, electric equipment, especially in the automatic welding, welding current, voltage stability.

+ including: constant and variable speed two type, with manual and automatic welding respectively, Also can use with welding robot.

* * tail stock and L can be designed according to customer requirements into mobile.

Notes:

a) For more details of Positoner capacity see sheets ,

b) For ordering an adjustable height positioner add the prefix AH. Available for models WP 5 and smaller

c) Control cabinet includes: power indicator, speed indicator, speed adjustment, overturn (tilt) up and down, forward and reverse rotation, stop, fault & reset

d) Remote control box allows adjustment of table rotating speed (digital display in RPM/min), forward and reverse rotation, and stop

e) "T" shaped channels on work table surface

f) Shot blasted frame at SA 2 ½ before being painted

g) Custom built Welding Positioners available

h) The information contained in this brochure is intended to beaccurate. However the manufacturer retain the rights to make changes in design which may not be include herein

Optional:

i) Foot control pedal for changing rotation direction and stop,

ii) variable speed on tilt

Head & tail stock positioner widely used in all line of mechanical welding plant, deflection of workpiece can make parallel axis of rotation to ship welding seam deflection. The structural features:

+ worm gear and worm reducer, compact structure, high reliability.

+ slewing bearing providing higher resistance to overthrow force and torque.

+ former board cabinet, thickening, strength, higher stability.

+ welding box frame, high stiffness distortion.

+ Excellent welding wire, electric equipment, especially in the automatic welding, welding current, voltage stability.

+ including: constant and variable speed two type, with manual and automatic welding respectively, Also can use with welding robot.

* * tail stock and L can be designed according to customer requirements into mobile.

| Model | Rated load Cap(tons) | Power (kW) | Driving Moment Newtons-meeter | Max centroid Eccentricity (mm) | Table | Revolve center height H (mm) | Weight (tons) | |

| HT Series | Speed (RPM) | Diameter ΦD(mm) | ||||||

| HT0.5 | 0.5 | 0.75 | 2100 | 300 | 1.5 | 600 | 600 | 0.9 |

| HT1 | 1 | 0.75 | 2100 | 200 | 1.5 | 800 | 800 | 1.5 |

| HT2 | 2 | 1.1 | 4600 | 150 | 1.5 | 800 | 800 | 1.8 |

| HT3 | 3 | 1.5 | 6400 | 150 | 1.5 | 800 | 800 | 3.2 |

| HT5 | 5 | 1.5 | 9000 | 150 | 1 | 800 | 800 | 5.1 |

| HT7.5 | 7.5 | 2.2 | 13500 | 150 | 1 | 1000 | 800 | 8 |

| HT10 | 10 | 2.2 | 13500 | 100 | 1 | 1000 | 1000 | 10 |

| HT15 | 15 | 3.7 | 18000 | 100 | 1 | 1000 | 1000 | 13 |

| HT20 | 20 | 3.7 | 30000 | 100 | 0.8 | 1000 | 1000 | 14 |

| HT30 | 30 | 4 | 36000 | 100 | 0.5 | 1000 | 1000 | 20 |

| HT50 | 50 | 4 | 60000 | 100 | 0.4 | 1500 | 1200 | 23 |

| HT100 | 100 | 5.5 | 120000 | 100 | 0.2 | 1500 | 1200 | 26 |

| Model | Rated load Cap(tons) | Power (kW) | Max Gravity height (mm) | Max centroid Eccentricity (mm) | Table | 90 Max Rotation Æ (mm) @ 90degree | Tilt Angle (degree) | Dimensions | Weight (tons) | ||||

| EWP Series (SHB ) | Rotation | Tilt | Speed (RPM) | Diameter ΦD(mm) | |||||||||

| Rotation (variable) | Tilt (constant) | L*W*H (mm) | Emin-max/p(m) | ||||||||||

| EWP 1 | 1 | 1.1 | 1.5 | 250 | 150 | 0.12 - 1.2 | 0.67 | 900 | 1500 | 0-135 | 1210*1500*1670 | 1.1*1.7/0.15 | 1.2 |

| EWP 2 | 2 | 1.1 | 1.5 | 300 | 150 | 0.05 - 0.5 | 0.23 | 1200 | 2000 | 0-135 | 1780*1320*1800 | 1.2*1.8/0.15 | 1.6 |

| EWP 4 | 4 | 1.5 | 2.2 | 300 | 150 | 0.05 - 0.5 | 0.23 | 1400 | 2100 | 0-120 | 2140*1500*2100 | 1.3*1.9/0.15 | 2.8 |

| EWP 6 | 6 | 2.2 | 3 | 300 | 150 | 0.05 - 0.5 | 0.14 | 1500 | 2500 | 0-120 | 2760*1630*2600 | 1.6*2.4/0.2 | 5.0 |

| EWP 8 | 8 | 2.2 | 4 | 400 | 200 | 0.02-0.2 | 0.14 | 1600 | 2800 | 0-120 | 2950*1850*2800 | 1.7*2.6/0.22 | 6.5 |

| EWP 10 | 10 | 3 | 5.5 | 400 | 200 | 0.02 - 0.2 | 0.14 | 1800 | 3000 | 0-120 | 3300*2000*3100 | 1.9*2.9/0.24 | 7.8 |

| EWP 15 | 15 | 3 | 5.5 | 400 | 200 | 0.02-0.2 | 0.1 | 2000 | 3200 | 0-120 | 3600*2200*3450 | 2.1*3.2/0.25 | 12 |

| EWP 20 | 20 | 4 | 7.5 | 400 | 200 | 0.02 - 0.2 | 0.1 | 2200 | 3400 | 0-120 | 4000*2400*3800 | 2.3*3.5/0.3 | 18 |

Notes:

a) For more details of Positoner capacity see sheets ,

b) For ordering an adjustable height positioner add the prefix AH. Available for models WP 5 and smaller

c) Control cabinet includes: power indicator, speed indicator, speed adjustment, overturn (tilt) up and down, forward and reverse rotation, stop, fault & reset

d) Remote control box allows adjustment of table rotating speed (digital display in RPM/min), forward and reverse rotation, and stop

e) "T" shaped channels on work table surface

f) Shot blasted frame at SA 2 ½ before being painted

g) Custom built Welding Positioners available

h) The information contained in this brochure is intended to beaccurate. However the manufacturer retain the rights to make changes in design which may not be include herein

Optional:

i) Foot control pedal for changing rotation direction and stop,

ii) variable speed on tilt