Informazioni di Base.

Model No.

KTG-60

modello

Ktg-60

peso massimo di carico

60 tonnellate

diametro del tubo adatto

750 mm

diametro rullo in gomma

440 mm

velocità lineare del rullo

100 mm/min

tempo di consegna

5 giorni

colore

personalizzato

garanzia

1 anno

quantità ruote

4 ruote

materiale ruota

rotatore a ruota in poliuretano e acciaio

modo regolabile

rotatore di saldatura regolabile a vite

pagamento

T/T L/C

motore di azionamento

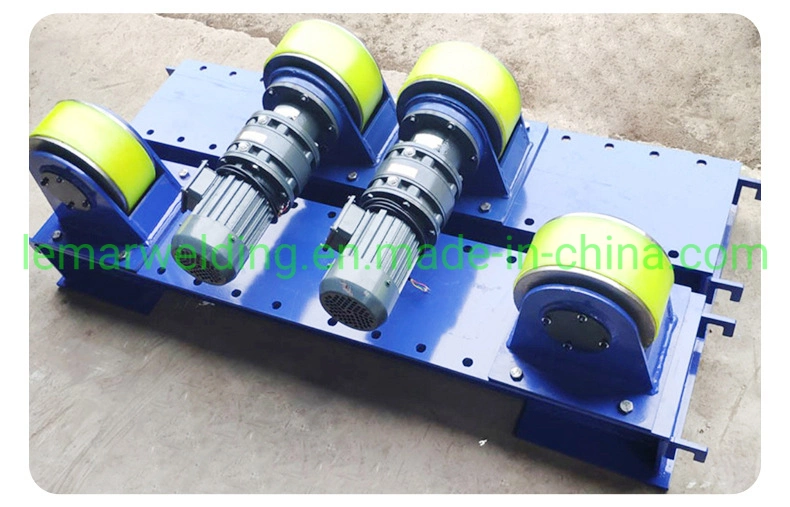

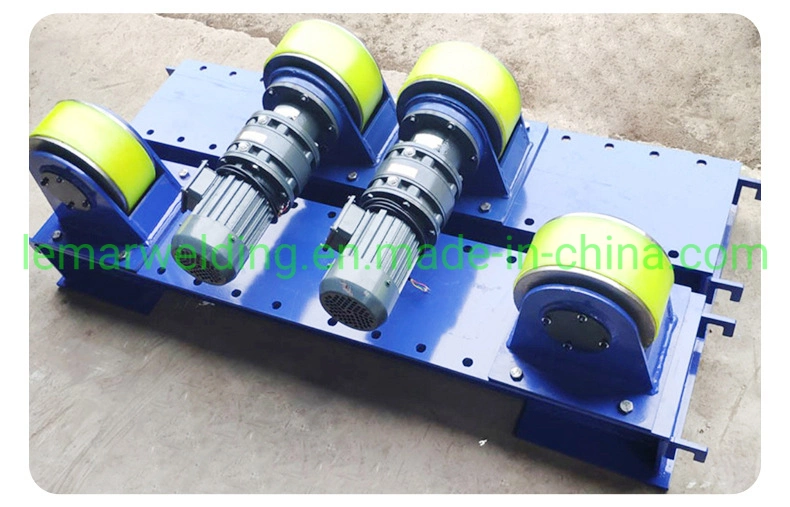

4 kw*2

dimensioni del rotatore attivo

1410*880*650mm

dimensioni rotatore condotto

1310*680*450mm

Pacchetto di Trasporto

Wooden Box

Specifiche

personalizzato

Marchio

Lemar

Origine

Wuxi, China

Codice SA

8428909090

Capacità di Produzione

10000 PCS/Year

Descrizione del Prodotto

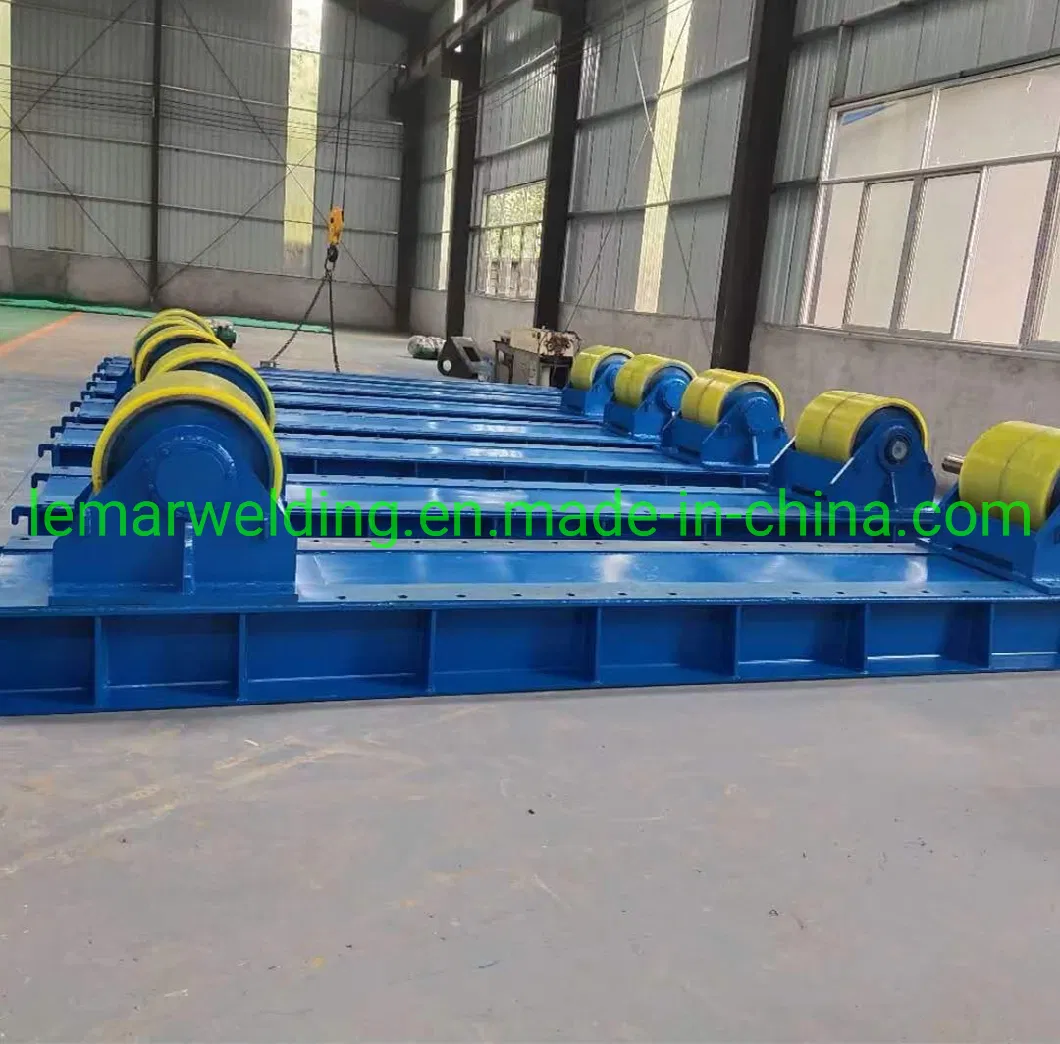

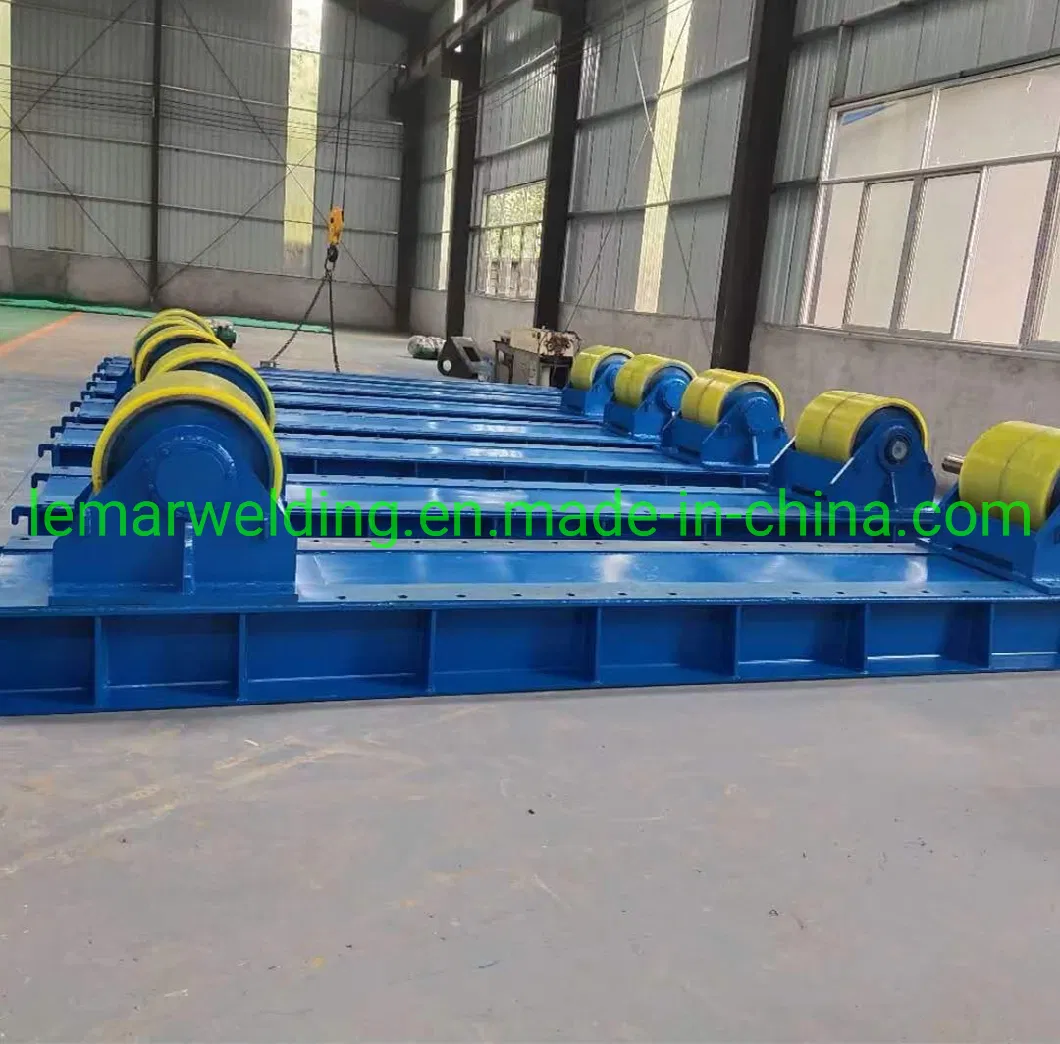

Automatic welding machine Conventional turning rolls welding rotators

The standard rotating roll rotators consist of a driver wheels and a freewheeling companion idler wheels.

The workpiece is supported at one end by the driver, who also gives it rotary motion.

The idler set only serves to sustain the rotating other end of the workpiece.

Each driver and idler roll has separate load ratings and capacities.

Various materials for Turning Roll Wheels:

Rubber wheel Rotator

Steel wheel Rotator

Polyurethane wheel Rotators

etc.

Specifications:

Specifications:

How to use Automatic welding rotators turning rolls correctly?

How to use Automatic welding rotators turning rolls correctly?

1. In order to ensure the performance of the adjustable and self aligning welding rotator, all transmission parts should be regularly or irregularly lubricated and inspected, and the cycloid reducer must be inspected every month to replenish the lubricating oil.

2. The working principle of Welding turning rolls is to use friction to do work. All transmission parts are not lubricated and are strictly prohibited to use.

3. Before restarting the long-term sealed roller frame, the grease must be replaced to avoid damage to the machine.

4. During use, the rollers are in contact with the weldment, and the weld seam or sharp parts are strictly prohibited from touching the rollers, so as not to damage the rollers.

5. When hoisting and placing workpieces, it is strictly forbidden to hit the rollers vigorously to prevent damage to the rollers or other components. When the equipment is not fixed, a strong impact may cause the equipment to overturn.

6. When welding turning rolls are used for small-diameter cylinders, if there is axial movement of the cylinder, the adjusting bolts under the arc-shaped plate can be adjusted to adjust the lifting position of the rollers to ensure that the working position of the cylinder is in a proper state .

The standard rotating roll rotators consist of a driver wheels and a freewheeling companion idler wheels.

The workpiece is supported at one end by the driver, who also gives it rotary motion.

The idler set only serves to sustain the rotating other end of the workpiece.

Each driver and idler roll has separate load ratings and capacities.

Various materials for Turning Roll Wheels:

Rubber wheel Rotator

Steel wheel Rotator

Polyurethane wheel Rotators

etc.

Model

| Loading Capacity (kg) | Pipe/Tank Diameter (mm) | Rubber Roller Dia. & Width (mm) | Roller Speed (m/h) | Motor Power (kw) |

Speed Adjust

| |

Rubber Roller | Steel Roller | ||||||

KTG-5 | 5000 | Φ250-2800 | Φ250*100 | Φ240*20*2 | 6-60 | 0.75 | Variable Frequency Drive (VFD)

|

KTG-10 | 10000 | Φ320-2800 | Φ300*120 | Φ290*25*2 | 1.1 | ||

KTG-20 | 20000 | Φ500-3500 | Φ350*120 | Φ340*30*2 | 1.5 | ||

KTG-30 | 30000 | Φ600-3800 | Φ350*120 | Φ340*30*2 | 2.2 | ||

KTG-40 | 40000 | Φ600-4200 | Φ400*120 | Φ390*40*2 | 3 | ||

KTG-50 | 50000 | Φ700-4500 | Φ400*120 | Φ390*40*2 | 4 | ||

KTG-60 | 60000 | Φ750-4800 | Φ450*120 | Φ440*50*2 | 4 | ||

KTG-80 | 80000 | Φ850-5000 | Φ500*120 | Φ490*60*2 | 5.5 | ||

KTG-100 | 100000 | Φ1000-5500 | Φ500*120 | Φ490*70*2 | 7.5 | ||

KTG-150 | 150000 | Φ1100-6000 | Φ500*120 | Φ600*Φ280 | 2*5.5 | ||

| KTG-250 | 250000 | Φ1200-7000 | / | Φ700*380 | 2*5.5 | ||

| KTG-500 | 500000 | Φ1800-8000 | / | Φ850*350 | 2*7.5 | ||

1. In order to ensure the performance of the adjustable and self aligning welding rotator, all transmission parts should be regularly or irregularly lubricated and inspected, and the cycloid reducer must be inspected every month to replenish the lubricating oil.

2. The working principle of Welding turning rolls is to use friction to do work. All transmission parts are not lubricated and are strictly prohibited to use.

3. Before restarting the long-term sealed roller frame, the grease must be replaced to avoid damage to the machine.

4. During use, the rollers are in contact with the weldment, and the weld seam or sharp parts are strictly prohibited from touching the rollers, so as not to damage the rollers.

5. When hoisting and placing workpieces, it is strictly forbidden to hit the rollers vigorously to prevent damage to the rollers or other components. When the equipment is not fixed, a strong impact may cause the equipment to overturn.

6. When welding turning rolls are used for small-diameter cylinders, if there is axial movement of the cylinder, the adjusting bolts under the arc-shaped plate can be adjusted to adjust the lifting position of the rollers to ensure that the working position of the cylinder is in a proper state .